In our last article we took our readers through the American Caddy Vac construction process. In that article (and corresponding video) we looked at the local construction process that takes place at a trusted facility very close to our headquarters.

In this article, we’re going to more specifically discuss the materials that go into that construction. We’ve been in the duct cleaning business even longer than we have been in the cleaning unit business, so we have an informed understanding of the type of pressure exerted on every square inch of these units during the cleaning process. The powerful Northern Blower fans we use to create the suction needed to properly put the air duct system in a house or business under consistent negative pressure also puts a tremendous strain on the cleaning unit. If the materials used to build it aren’t up to that strain, along with all the other strain of daily use, it simply won’t last very long.

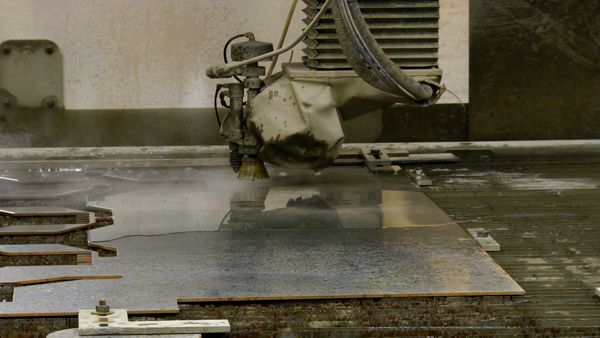

That’s why at the structural level, all of our components are made of heavy duty steel sheets. The walls and inner frames of the unit are all heavy, thick, steel… able to withstand whatever the work day will throw at it for decades of use.

That’s also why those steel components are welded together, NOT BOLTED. We’ve seen it ourselves, and we hear about it from our customers all the time. Cleaning units that are bolted together simply fall apart under the pressure and vibration involved in duct cleaning. Even before they fall apart they require extra maintenance, because those nuts loosen and need to be tightened regularly. When you have a unit like ours, where all the structural features are welded together, those factors are never even a consideration. At the end of the day, the American Caddy Vac will still be in one piece, utterly reliable.

Components in the American Caddy Vac that do not require the strength of steel are still made with extremely high grade heavy duty aluminum. These parts are over-engineered, designed to last at least as long as the rest of the unit.

When it’s time to trim out your vehicle, with doors and hinges, adding cleaning elements, compressors, hose reels, bypass chutes, custom cabinets and any other standard and optional components, American Caddy Vac still uses only parts that are made to last. We don’t cut corners anywhere! That means when you have used your American Caddy Vac for five years, it is unlikely that you will need to replace anything. In fact, that is one of the things we hear over and over again from our customers… they are surprised at how little repair and replacement they have to do. Typically, our stuff just doesn’t break. Our competitors simply can’t say that.

So when it is time to purchase your next (or first!) cleaning unit, ask yourself this question: “Do I want a cleaning unit that won’t break?” If the answer is yes, then your decision is easy. You want an American Caddy Vac. Give us a call and we’ll help you get started!